智能功率模块让热泵更智能

二月 29, 2024

Share:

The demand for more efficient power semiconductors is on the rise as businesses adapt to a low-carbon future. Minimizing the overall cost and footprint of the system while enhancing efficiency is a crucial objective that needs to be considered while developing power semiconductor solutions. Intelligent power modules (IPMs) are one such solution that has gained significant attention in the heat pump market. These compact and highly integrated modules provide high power density and advanced control and monitoring capabilities, making them an ideal choice for heat pumps.

Learn more about intelligent power modules (IPMs).

The Importance of Heat Pumps

According to Eurostat data, about 50% of all energy consumed in the European Union (EU) is used for heating and cooling, and more than 70% still comes from fossil fuels (mostly natural gas). In the residential sector, around 80% of the final energy consumption is used for space and water heating.

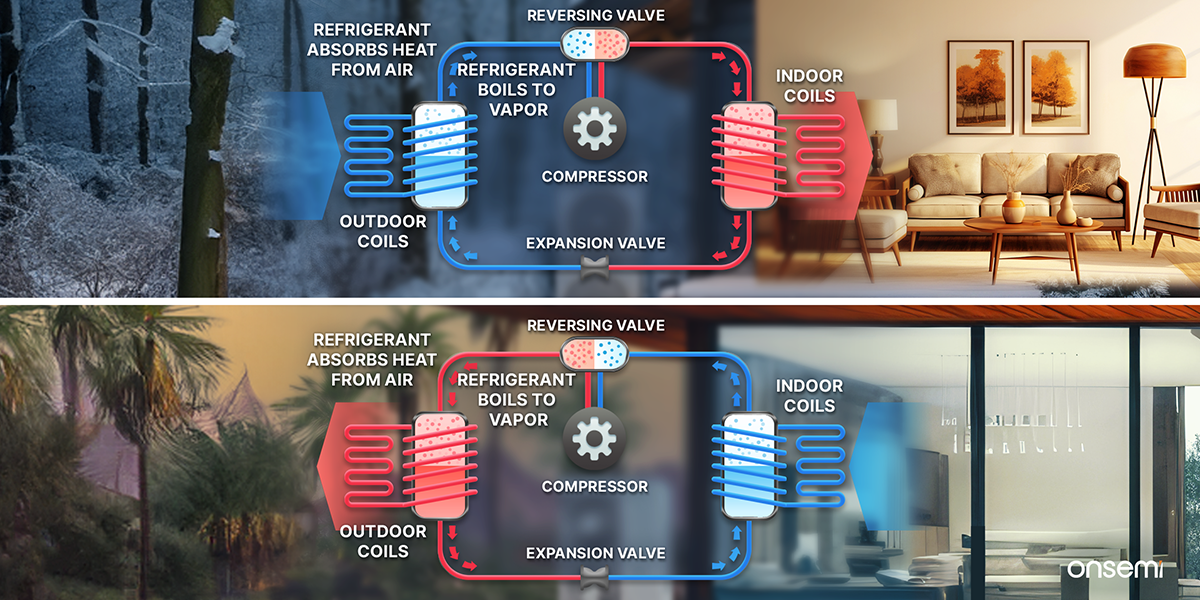

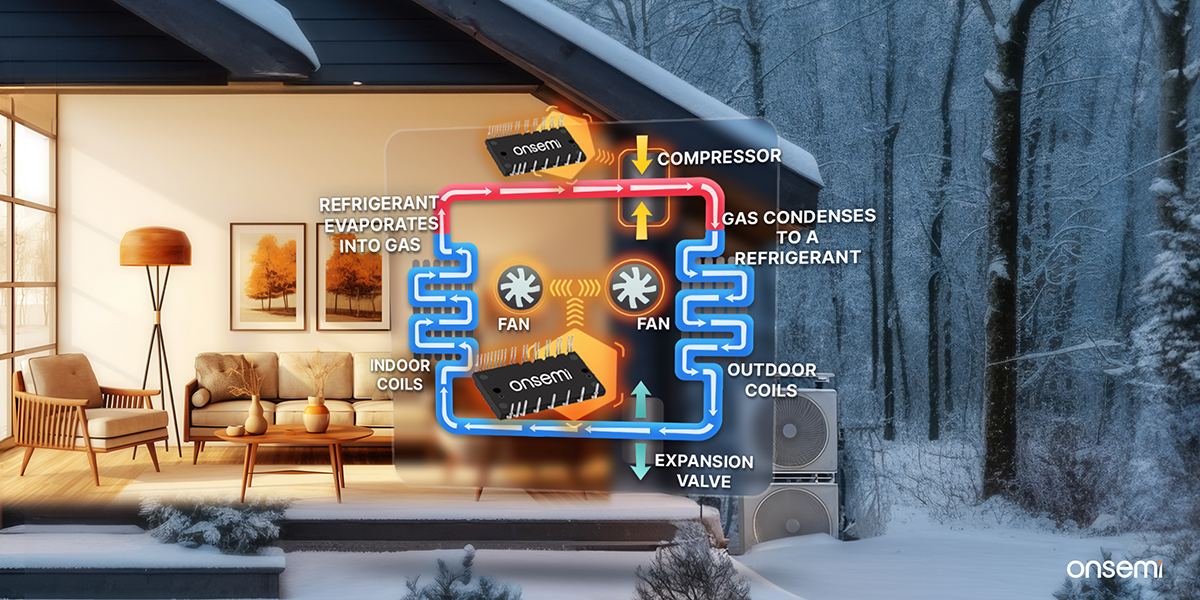

Heat pumps (Figure 1) can deliver heating, cooling, and dehumidification needs and are a proven and sustainable solution for heating powered by electricity. They are an environmentally friendly option for your home and office, helping us move away from fossil fuels to more renewable energy technologies. With global concerns about energy security and climate commitments, heat pumps are emerging as the primary tool for decarbonization in space and water heating systems.

The number of heat pumps installations globally will rise from 180 million in 2020 to around 600 million in 2030, according to the International Energy Association (IEA). At least three times more efficient than traditional fossil fuel boilers, heat pumps are preferred and its installation in individual buildings is forecasted to rise from 1.5 million per month currently to around 5 million by 2030 (Source: IEA). In the U.S., the Inflation Reduction Act includes tax credits and rebates that can cover up to 100% of the costs, depending on household eligibility.

The Role of IPMs in Heat Pump Efficiency

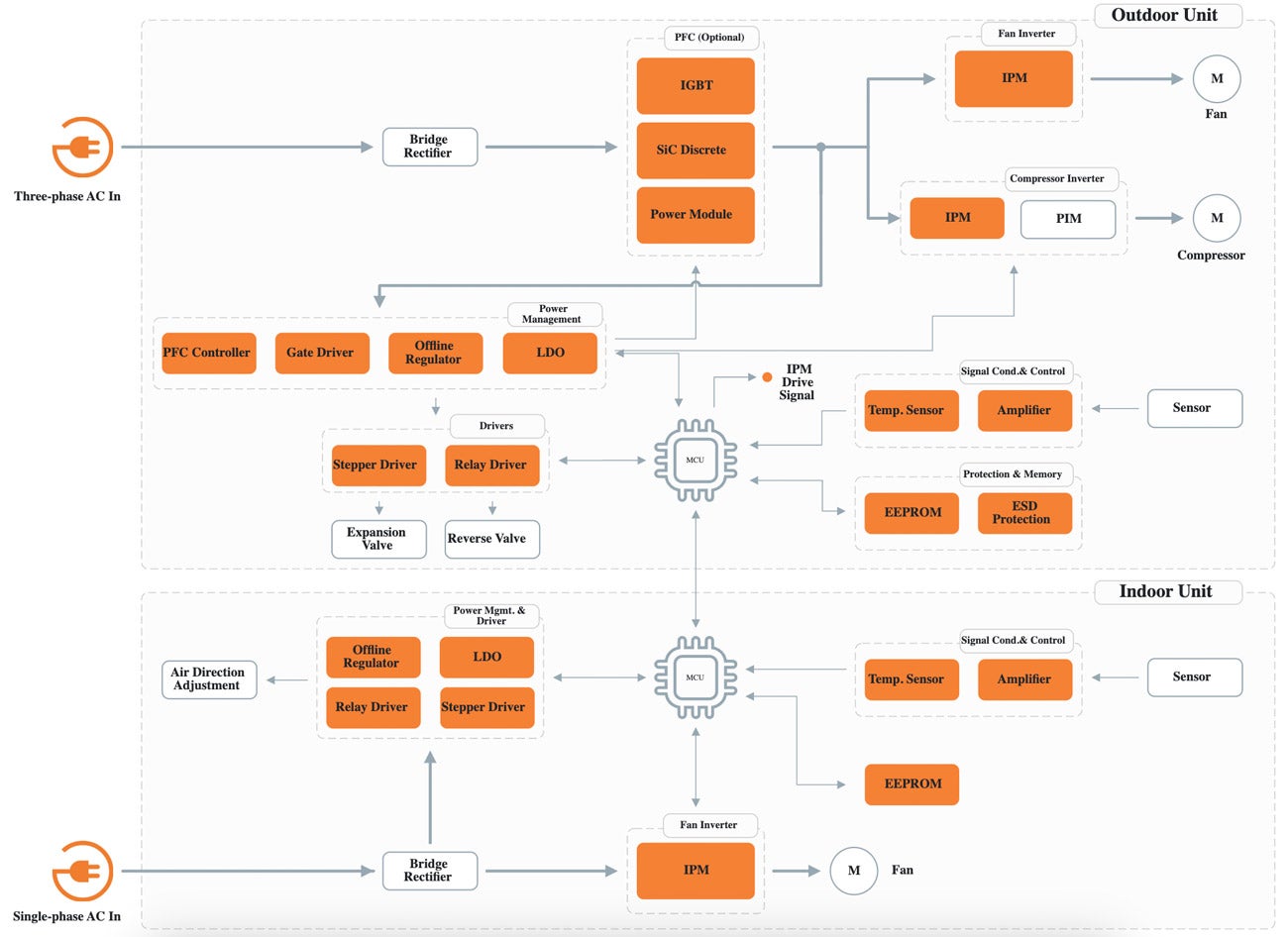

Intelligent power modules (IPMs) are crucial in controlling the power flow to inverter compressors and fans in heat pump systems. (Figure 2) These modules adjust the frequency and voltage of power supplied to three-phase motors and contribute to achieving higher energy efficiency standards for compressors and pumps. For example, coolers using IPMs for their inverter systems reduce power by 30% compared to non-inverter systems.

IPMs are prevalent in various applications and systems. Owing to their high level of integration, whether in the power stage, drivers, or protections, IPMs allow for shorter development phases.

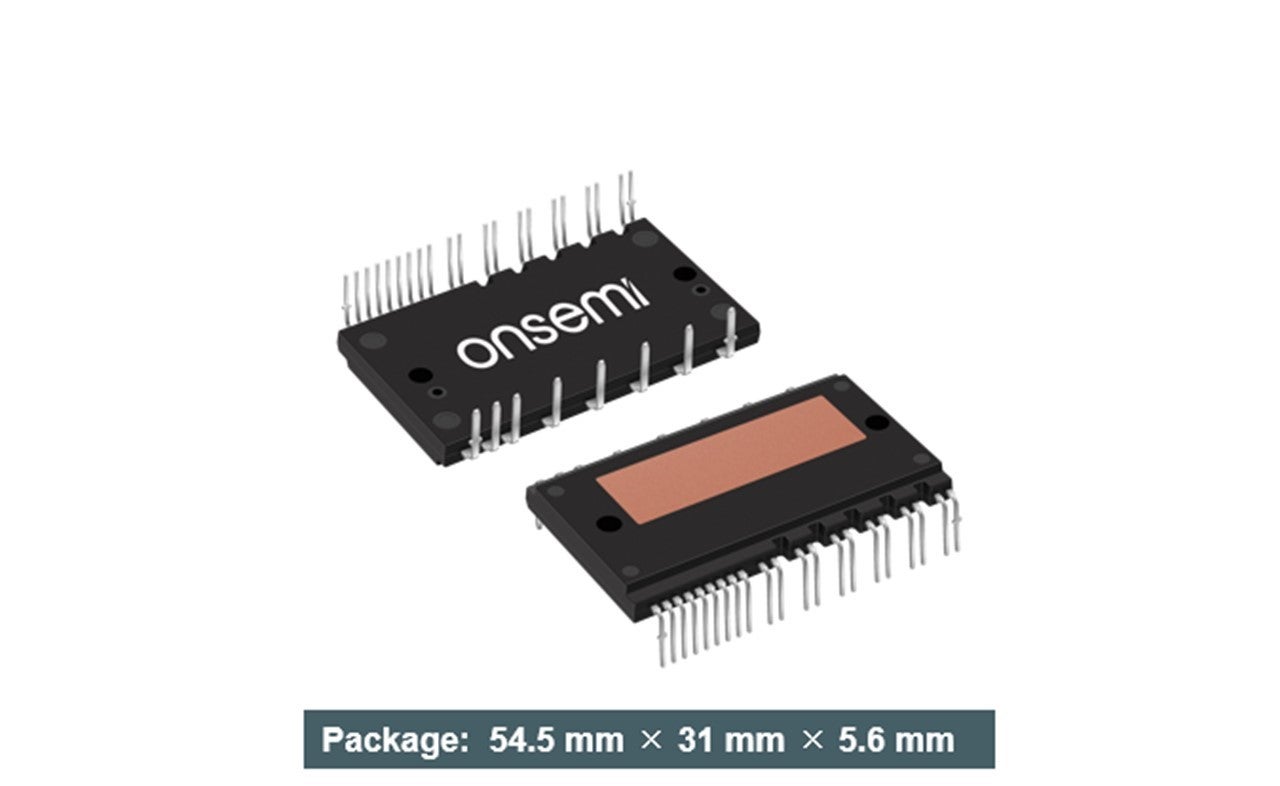

onsemi has recently unveiled a new family of 1200 V SPM31 IPMs, setting a new standard for three-phase inverter applications. This groundbreaking technology not only addresses the growing need for energy efficiency but also focuses on reducing system costs and improving overall performance. With new and improved features, the SPM31 IPMs are a game-changer in the heat pump market.

Enhanced Efficiency and Power Density

The SPM31 IPMs incorporate the latest 7th generation of IGBT Field Stop (FS7) technology, making them highly efficient and robust. The well-optimized active cell design and buffer profile, coupled with narrow electrical parameter distribution, eliminates short circuit oscillation in both single and parallel device operations. This technology uses a submicron trench gate cell pitch that increases channel density to reduce the conduction losses. The gate capacitance is optimized for smooth switching waveforms and low switching losses. On the emitter side, multiple FS layers enhance blocking capability and reduce drift layer thickness, resulting in lower conduction and switching energy losses. The FS7 IGBT development focuses on optimizing both Vcesat and Eoff to achieve state-of-the-art device performance.

This technology results in minimized EMI, up to 10% a remarkable reduction in power losses, up to 9% increase in power density, and a 20% size reduction in IGBT chip die size compared to previous generation products. As a result of the improved power density, designers can use a simplified layout to free up valuable space in the heat pump system while improving efficiency. The SPM31 IPMs are available in multiple current rating line-ups ranging from 15 to 35 Amps (A).

Advanced Features for Reliable Operation

onsemi’s SPM31 IPMs come equipped with an array of advanced features to ensure reliable operation. The modules include gate driver ICs and various on-module protection features, such as:

- Under-Voltage Lockouts: The SPM31 IPMs protect against low voltage conditions that can cause unpredictable operation or even damage to the system.

- Over-Current Shutdown: This feature provides protection against excessive current flow, which can cause permanent damage to the system.

- Thermal Monitoring: The SPM31 IPMs can accurately sense temperature, allowing for proper thermal management and preventing overheating.

- Fault Reporting: The modules can detect and report various faults to the system, providing early warning signs for potential issues.

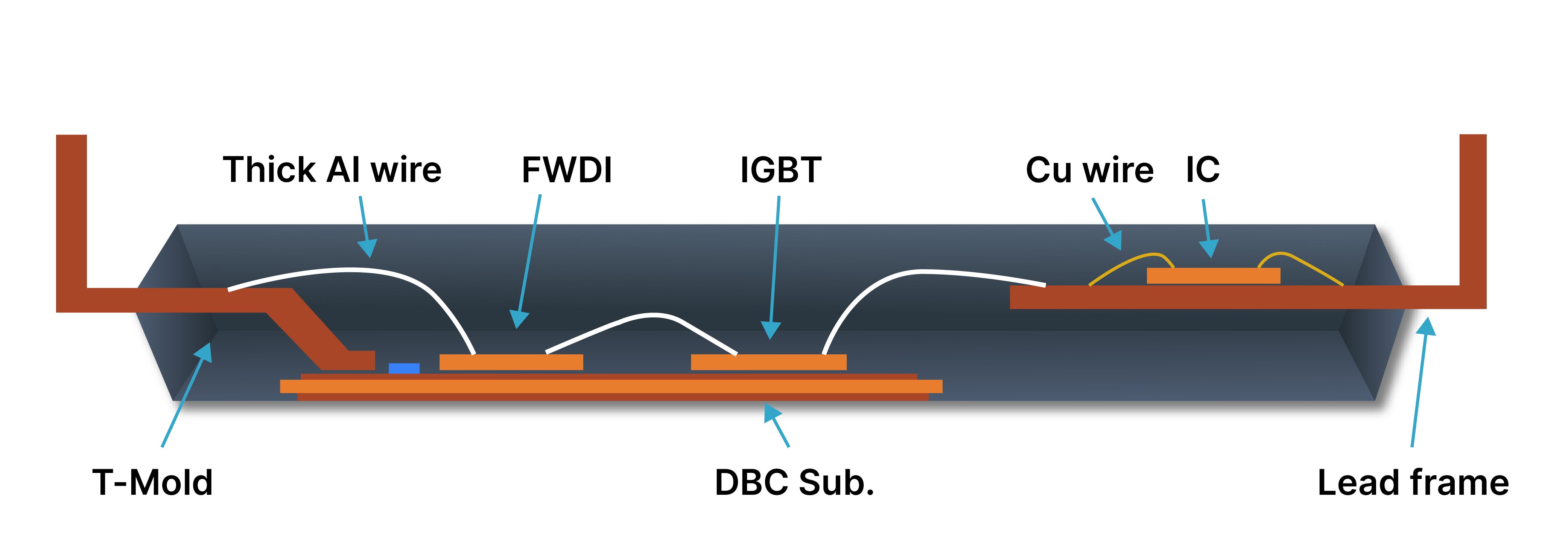

Additionally, the SPM31 IPMs use a direct bond copper substrate (Figure 5), providing superior thermal performance. These features enhance the robustness of the modules and contribute to their suitability for a wide range of applications. The versatility of the SPM31 IPMs makes them an ideal choice for various inverter drive applications including HVAC, heat pumps, variable frequency drives (VFD), industrial pumps and fans, and servo motors.

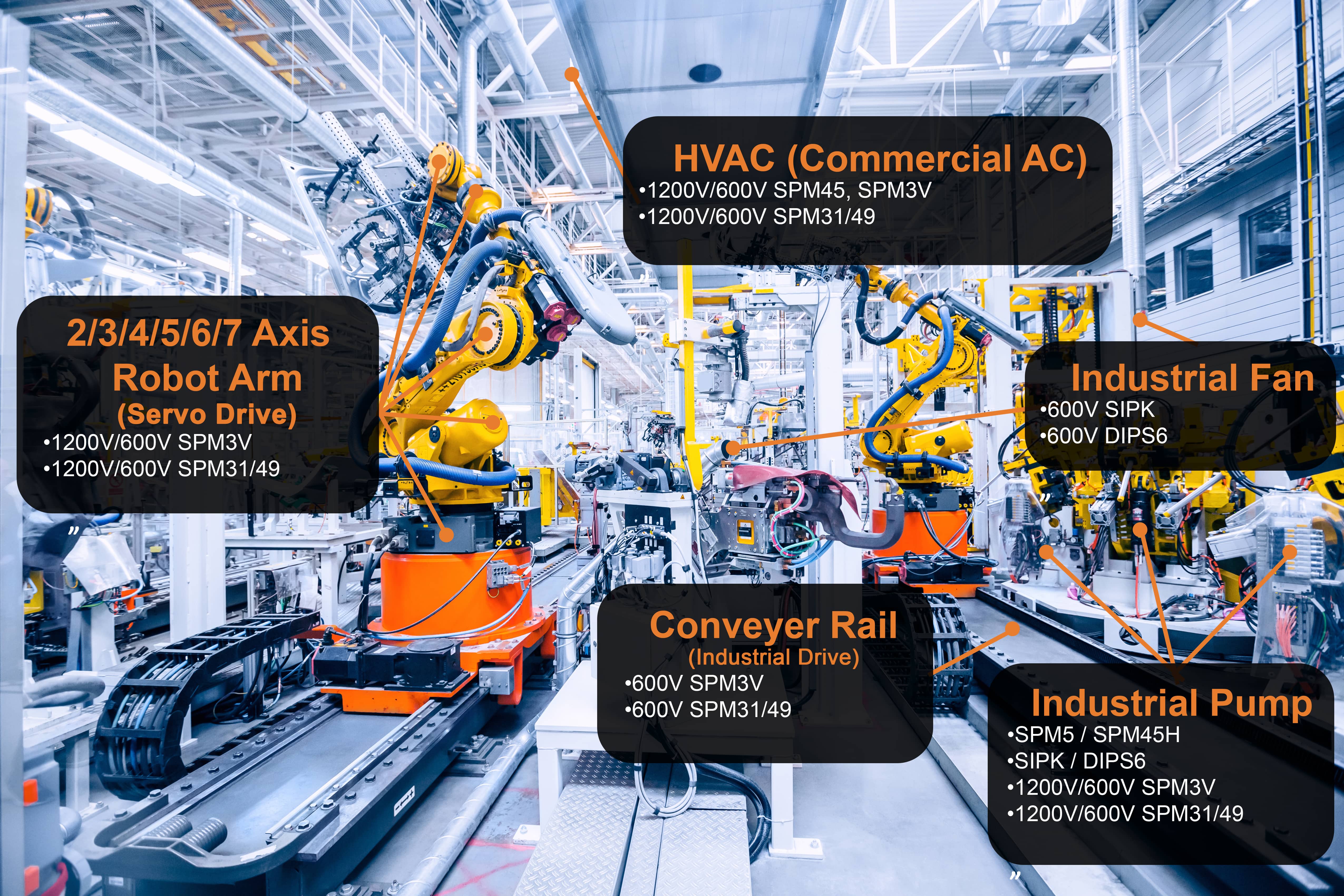

Alongside the SPM31, onsemi has a versatile IPM product portfolio. (Figure 6)

The adaptability of these modules showcases their potential to revolutionize multiple industries by providing efficient and compact solutions.

A Leap Forward for Heat Pump Applications

The SPM31 IPMs are a significant advancement for heat pumps. The IPMs provide a compact, high-performance solution that helps engineers design more efficient, reliable, and cost-efficient systems for industrial applications.

Learn more about the SPM31 IPMs and how these modules can revolutionize your heat pump system.

Additional Resources:

Featured

Intelligent Power Modules (IPMs)

High voltage power modules with integrated gate drivers for consumer, industrial, and automotive applications. Offering a large range of 3-phase inverter modules covering power levels from 50 W to 10 kW. Available in different topologies including PFC and input bridge rectifier.