区域控制架构基础入门:降低车辆系统开发复杂性

五月 01, 2025

Share:

Thirty years ago, cars were marvels of mechanical engineering, but they were remarkably simple by today’s standards. The only electronics in an entry-level car would have been a radio and electronic ignition. The window winders were manual. The dashboard had an electromechanical speedometer and some warning lights. Power flowed directly from the battery to the headlights via a switch on the dashboard. There was no ABS, no airbags, and no centralized computer. Everything was analog and isolated.

Fast forward to today, vehicles are packed with hundreds of features, many mandated by regulation or demanded by consumers. To implement these features, automakers bolted on electronic control units (ECUs) one after another. Each system (braking, lighting, infotainment, and more) gained its own ECU, software and wiring. Over time, this created an ever-more-complex web of over 100 to 150 ECUs in a single vehicle.

To break through this complexity, automakers are embracing software-defined vehicle (SDV) architectures. SDVs aim to centralize software control, making it easier to update, manage, and extend features. But even with this shift, the underlying wiring and distributed hardware can remain a bottleneck unless automakers also rethink the vehicle’s physical architecture.

Enter zonal architecture: a modern, location-based design strategy that complements SDV principles and dramatically simplifies vehicle systems.

What Is Zonal Architecture?

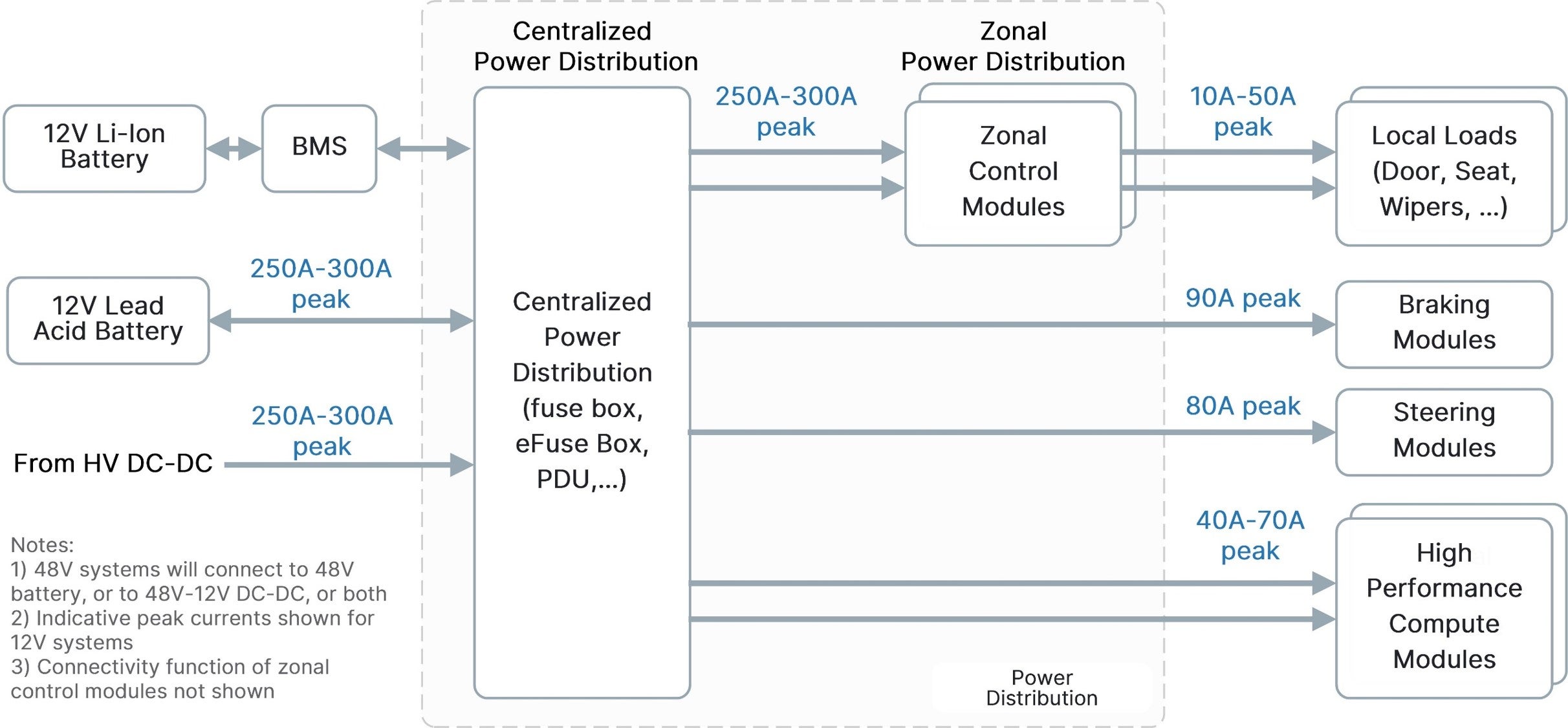

Zonal architecture is a paradigm shift, organizing vehicle electronics by location instead of by function. Instead of assigning each subsystem its own dedicated ECU, zone controllers are installed in each region of the vehicle, such as the front-left corner, rear-right corner, or cabin. These controllers manage local devices like lights, switches, and sensors within their respective zones. Rather than each component running its own software, the zone controller acts as a hub, handling power distribution and data communications.

These zone controllers connect to a central computer, which houses the core software that defines how the vehicle behaves. So instead of having separate ECUs for central locking, lighting, or climate control, the central compute unit makes decisions, while zone controllers carry them out.

This shift replaces hundreds of point-to-point wires with a simpler, more manageable zonal layout. By doing so, it dramatically improves design clarity and system efficiency.

Real-World Challenges of Implementing Zonal Architecture

While the benefits are compelling, implementing zonal architecture isn’t without its challenges. For one, not all edge modules can be completely stripped of intelligence. Some components, such as advanced lighting systems, still require local processing for performance, safety, or proprietary functionality. Tier 1 suppliers deliver these modules with built-in software because they possess specialized knowledge of how to program and control them.

This raises a core challenge for SDVs using zonal designs: balancing centralized control with localized flexibility. In many cases, carmakers handle the central compute software, while Tier 1s manage the embedded software for the modules they manufacture. A pure, software-only central brain is a goal, but compromises are often necessary.

The Role of Ethernet in Zonal Designs

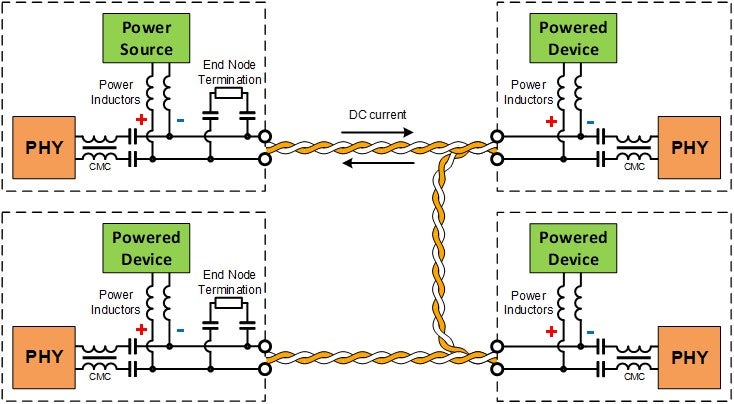

Traditional ECUs used legacy communication protocols like CAN and LIN, which were adequate for isolated modules but became unwieldy when scaled across a zonal architecture. That’s where automotive Ethernet, specifically 10BASE-T1S, comes into play.

10BASE-T1S is a low-speed (10 Mbps), multi-drop Ethernet standard designed specifically for automotive use. It enables multiple nodes (think headlights, turn signals, and door locks) to share a single twisted pair of wires, reducing the need for expensive point-to-point connections.

This approach simplifies cabling, lowers cost, and leverages Ethernet’s mature ecosystem, including time synchronization and error recovery, without the overhead of higher-speed Ethernet like 100BASE-T1 or gigabit Ethernet, which are unnecessary for low-bandwidth devices.

Smart Switches in Power Distribution

Zonal controllers not only relay data, but also distribute electrical power to the components in their zone. This means they play a critical role in system safety and diagnostics. onsemi’s smart switches go far beyond basic circuit protection. These intelligent devices offer:

- Voltage and current monitoring for each channel

- Support for automotive safety standards such as ASIL B and ASIL D

- Fail-safe and fail-operational modes, ensuring continuity of function even when faults are detected

For example, in the event of a malfunction, a smart switch can reduce power, isolate the fault, or enter a safe fallback mode rather than shutting down critical systems like headlights entirely. This level of insight and control is critical and mandatory for higher levels of automated driving.

Benefits of Zonal Architecture

Zonal architecture delivers five major advantages across vehicle development, production and operation:

- Reduced wiring harness complexity and weight: Fewer wires and connectors reduce both vehicle weight and build time.

- Lower cost of materials and assembly: Simplified wiring means reduced manufacturing cost and easier maintenance.

- Improved scalability: New features can be added or changed via software, without reengineering hardware layouts.

- Centralized software control: Streamlines development and enables over-the-air (OTA) updates, a key enabler of SDVs.

- Smarter feature coordination: Take lighting as an example. In legacy vehicles, flashing the headlights upon unlock required integrating multiple ECUs. In zonal designs, the central computer sends a single command, and the appropriate zone controller executes it—no redundant wiring or separate lighting logic required.

onsemi Is Helping Carmakers Transition to the Zonal Architecture

Zonal architecture represents a paradigm shift in how vehicles are designed and built. By grouping functions by physical location and leveraging Ethernet-based communications, automakers significantly reduce system complexity, wiring costs and maintenance challenges.

When combined with software-defined vehicle principles, zonal designs pave the way for faster innovation, greater customization, and smarter diagnostics.

With enabling technologies like 10BASE-T1S, Remote Control Protocol ICs, and intelligent power distribution, onsemi is helping carmakers bring this vision to life, delivering scalable, safe, and efficient zonal solutions that meet the evolving demands of modern mobility.

Additional resources: