从封装看功率芯片:碳化硅 T2PAK 封装的优势

十二月 04, 2025

Share:

The rise of electrification across electric vehicles (EVs), renewable energy systems, and AI data centers is putting increased pressure on power systems, demanding higher efficiency, smaller footprints and cooler operation. This presents an ever-present challenge: increased power density combined with shrinking system sizes often creates severe thermal bottlenecks.

This is the central challenge facing power systems designers today. Effectively managing heat has become a critical design hurdle. Global markets are accelerating the adoption of silicon carbide (SiC) technology, but thermal design is frequently a limiting factor. Traditional packaging solutions often struggle to meet the thermal demands of high-power SiC applications, necessitating a trade-off between switching performance and thermal efficiency.

New packaging solutions are providing thermal management and efficiency in today’s more demanding applications.

The Electrification Challenge

Power distribution boards are already overstressed, often having already met their maximum thermal limits. Engineers cannot afford to divert excess heat from power switches onto these boards.

Two MOSFET packages that are commonly known for their relatively high thermal performance are D2PAK (TO-263-7L) and TO-247-4L. But in tighter confines, their shortcomings are obvious:

- TO-247-4L offers satisfactory heat dissipation because it easily connects to the heatsink using a simple screw clip that leaves a sufficient thermal dissipation path. In small confines, the leads, conductive tracks, and capacitors in its vicinity can build up a large commutation loop — the sum of all parasitic inductances. The results may include big overshoots, reduced switching speeds and higher switching losses.

- D2PAK mitigates against the stray inductance problem because, as a surface mount device (SMD), its short copper traces minimize commutation loop areas. Compared to TO-247-4L, D2PAK does enable faster switching speeds. However, D2PAK is forced to dissipate its heat through the printed circuit board (PCB), resulting in larger thermal resistance between the heatsink and the device.

Designers need a solution that overcomes these compromises without sacrificing performance or increasing system size. Enter, the T2PAK.

What Makes T2PAK Different

The T2PAK combines onsemi’s industry-leading silicon carbide technology with one of the most widely adopted top-side cooled (TSC) packaging formats. T2PAK is uniquely designed to balance superior heat dissipation with excellent switching performance, combining the advantages of both TO-247-4L and D2PAK with no major drawbacks.

Video: T2PAK Explained: Top-Side Cooling Transforms SiC Power Design

The Top-Side Cooling Advantage

TSC enables direct thermal coupling between the MOSFET and the application heatsink in an SMD. This allows heat to be drawn away from the power distribution board and directly into the system’s cooling infrastructure or metal casing, bypassing the PCB thermal bottleneck encountered by D2PAK. The benefits include:

- Superior thermal performance — Dissipating heat directly into the heatsink reduces ambient operating temperatures.

- Thermal stress reduction — Drawing heat away from the main board reduces thermal stress on other components, helping to maintain lower PCB temperatures, while prolonging operational life and improving system reliability.

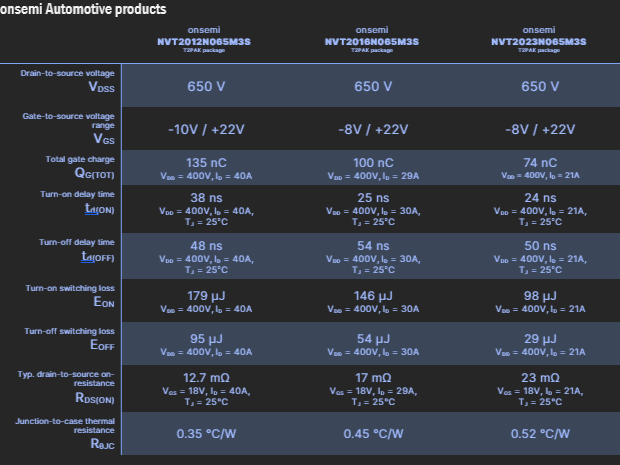

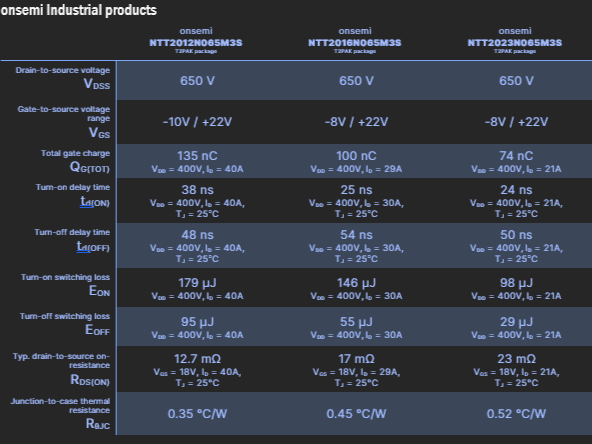

- Low stray inductance — Devices such as the superior-switching NTT2023N065M3S and NVT2023N065M3S feature very low total gate charge (≈74 nC) and output capacitance (≈195 pF), with greater reliability and reduced losses.

- Design flexibility — The combination of EliteSiC’s outstanding Figure of Merit (FOM) and the top-side cooled T2PAK allows for more efficient application designs with a smaller footprint.

The T2PAK portfolio offers a wide range of options, including planned releases of 12 mΩ, 16 mΩ, 23 mΩ, 32 mΩ, 45 mΩ, and 60 mΩ parts for the 650 V and 950 V EliteSiC M3S MOSFETs.

General technical characteristics

- Compliance: Meets IEC 60664-1 creepage standards for the shortest distance between two conductive parts along the surface of an insulating material between two conductive parts (5.6 mm minimum)

- Measured thermal performance: Junction-to-case thermal resistance as low as 0.35 °C/W for 12 mΩ device (better than D2PAK)

- Mounting flexibility: Compatible with liquid-gap fillers, pads and ceramic insulators for thermal stack optimization

Market Impact and Applications

Worldwide sampling of T2PAK has been under way throughout 2025 in Europe, the Americas, and Greater China. This package is well-suited for demanding industrial and automotive applications.

Electric vehicles

T2PAK is often the most requested package for EV applications such as on-board chargers (OBC), drivetrain components and EV charging stations. Since an OBC usually has access to the vehicle’s liquid cooling system, TSC allows heat from power switches to be drawn into the system by way of a thermally conductive interface.

Greater power efficiencies can be achieved by lowering stray inductance, because eliminating commutation loop issues leads to reduced switching losses. This, coupled with adherence to IEC creepage standards helps reinforce manufacturers’ safety pledges to their customers.

Industrial and energy infrastructure

TSC packages are rapidly gaining footholds in solar energy systems due to their superior thermal efficiency. T2PAK is proving to be ideal in new and advanced infrastructure applications such as solar power conversion and energy storage systems (ESS), T2PAK is proving to be ideal.

Hyperscale AI data centers

Data centers rely upon rack-mounted AC-DC and DC-DC power supplies and power distribution units. Entire hyperscale architectures are based around easy access to, and replacement of, these power units. As liquid cooling becomes commonplace in data centers, T2PAK’s native top-side cooling integrates well with cold-plate designs. Here, free-flowing coolant circulates within channels running alongside thermal interfaces attached directly to the hottest chips, transferring heat away from high-performance processors. Coupled with immersion cooling, cold plate designs are responsible for reducing greenhouse gas emissions by as much as one-fifth according to a recent study.

By overcoming thermal challenges, the T2PAK enables designers to unlock higher performance, greater reliability and simplified thermal management. Customers can achieve high power density with the T2PAK compared to conventional discrete packages.

The T2PAK is also suitable for:

- HV DC/DC converters (automotive and industrial)

- Industrial SMPS (Switched-Mode Power Supplies) for automation and robotics

- Industrial drives and high-efficiency DC-DC converters

Global Adoption & Future Outlook

As power systems evolve, future designs will increasingly rely on top-side cooling to meet stringent efficiency and size targets. onsemi is prepared to meet the moment by making its leading SiC technology available with the T2PAK package.

Conclusion

As electrification reshapes every industry, onsemi’s EliteSiC T2PAK is redefining what’s possible in high-efficiency power conversion. EliteSiC MOSFETs in the T2PAK TSC package represent a packaging advancement that serves as a strategic enabler for electrification. By providing superior thermal performance, reliability and design flexibility without the usual trade-offs, T2PAK overcomes the space and thermal constraints faced by industries worldwide. The onsemi T2PAK is available to the broad market, ensuring widespread access to this critical technology.

Learn more

Explore the EliteSiC T2PAK products, with portfolio expansion continuing.