利用 Premier图像传感器参考模块简化摄像头开发

十月 02, 2024

Share:

Introduction

Developing intelligent, high-performance vision systems is a lengthy and extensive process typically taking around six months. Improving time-to-market for these vision systems while optimizing engineering resources is critical to the success of these complex vision designs. To aid in the camera development process, onsemi has developed a reference module ecosystem for our image sensors called Premier Reference Image Sensor Modules (PRISM).

In this blog you will learn about the PRISM ecosystem, its benefits and how to get started with PRISM.

PRISM & its Benefits

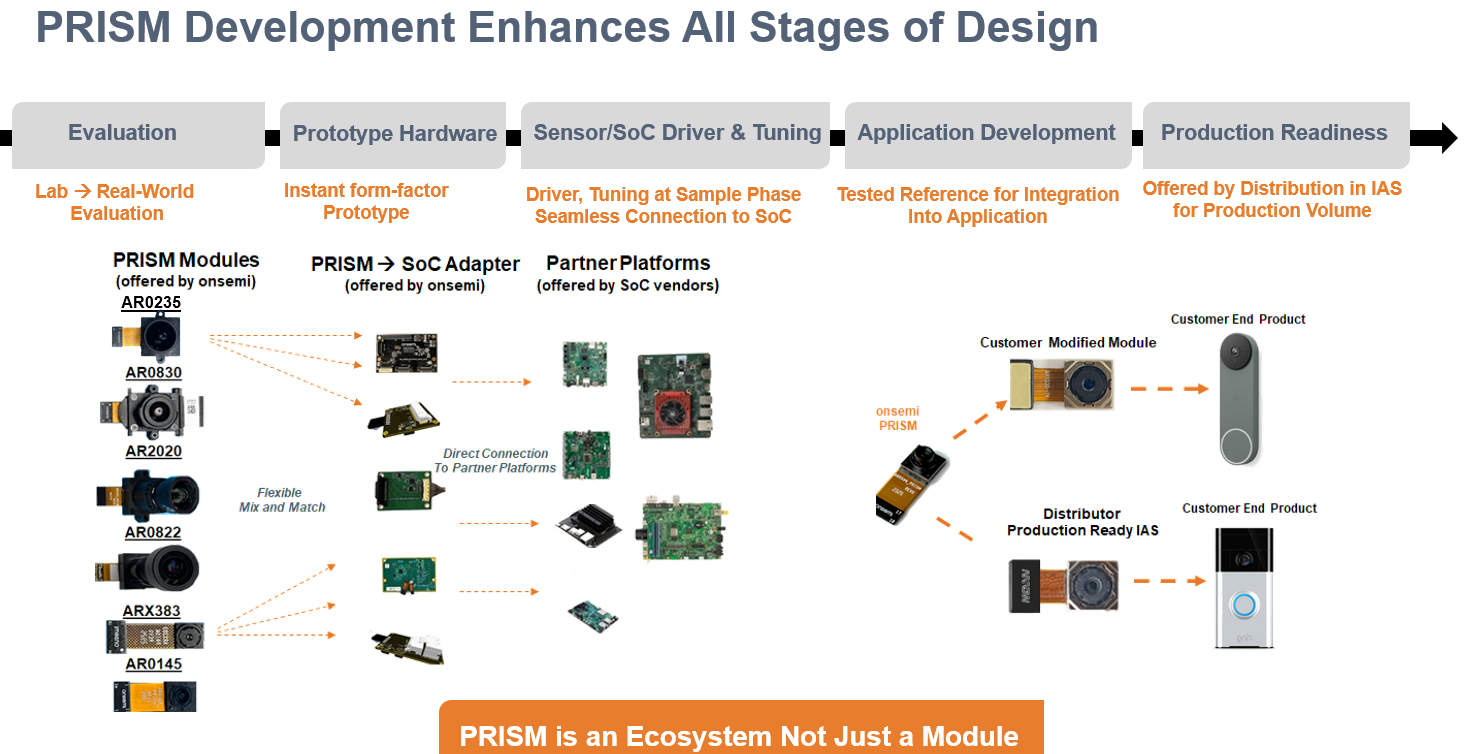

PRISM is a pre-optimized sub-system solution developed with onsemi’s industrial and commercial image sensors. Additionally, any new sensors introduced from onsemi will include PRISM as a part of its standard deliverables. The modules, combined with hardware adapters and ecosystem partner development kits, can be used for prototyping purposes and shorten the prototype design process for faster time to market.

A typical vision system consists of many elements including optics (lens), image sensor, sensor interface, image signal processor and application software or artificial intelligent (AI). The lens and sensor need to match perfectly within a proper form factor to maintain the quality of the input image. Any slight mismatch can result in artifacts that impact the overall system performance.

Alongside the modules, onsemi provides supporting material explaining how to further develop PRISM into a mass production design. Validation reports are provided under NDA for sensor’s performance baseline. A standardized interface of PRISM adaptor is also provided to connect PRISM to major AP/SoC platforms.

Figure 2 below provides a high-level outline of the PRISM ecosystem design stages.

Premier Reference Image Sensor Modules

Below, is a complete list of onsemi image sensor modules supported by the PRISM ecosystem.

- PRISM1M-AR2020CSSC130110-GEVB: This high-resolution 20 MP module is designed, built and validated with including video conferencing endpoints, AR/VR headsets and more. It’s innovative SmartROI feature delivers 20 MP performance without the needed bandwidth. The sensor drivers and base tuning are available with major SoC platforms.

- PRISM1M-AR0830CSSC130110-GEVB: This 8 MP sensor is designed, built and validated with lowest possible power consumption, impeccable imaging performance, and system saving features for applications including doorbell cameras, smart access and more. Its wake on motion feature allows for the lowest power consumption among comparable sensors in the industry.

- PRISM1M-ARX383CSSM130110-GEVB: Featuring the ARX383, this tiny 0.3 MP global shutter module is designed, built and validated with performance baseline for size-constrained applications including handheld QR barcode scanner, autonomous mobility and more.

- PRISM1M-AR0145CSSM130110-GEVB: This 1 MP global shutter module is designed, built and validated with performance baseline for applications including barcode reader, autonomous mobile robots and more.

- PRISM1M-AR0235CSSM130110-GEVB: Featuring the AR0235 image sensor, this 2 MP global shutter module is designed, built and validated with performance baseline for applications including barcode reader, autonomous mobile robots and more.

- PRISM1M-AR0822NPSC130110-GEVB: This 8MP module is designed, built and validated with performance baseline for applications that requires a HDR built in sensor especially in multiple camera system. Such multiple camera system usually consumes data transmission bandwidth between the sensor and ISP/SoC. Whether it is a single or multi-camera design, the AR0822 helps optimize HDR and reduce much of the bandwidth burden with its on-board eHDR.

Getting Started with PRISM

Expediate your prototype development process with our innovative image sensor modules and surrounding ecosystem tools. To learn more about PRISM, download our whitepaper or contact sales.

Additional resources

- Introducing onsemi’s Premier Reference Image Sensor Module (PRISM) Designed to Optimize Camera Development

- Video: Simplifying Camera Development with Premier Reference Image Sensor Modules

Featured

Machine Vision

Machine Vision is transforming industrial automation by enabling intelligent visual inspection, measurement, and decision-making across diverse sectors. As industries embrace digital transformation, machine vision systems are becoming essential for enhancing productivity, quality, and operational efficiency. These systems combine high-performance image sensors, advanced optics, and AI-powered processing to capture and analyze visual data in real time. From identifying defects in manufacturing lines to guiding robotic arms in assembly, machine vision ensures precision and consistency.

Driven by innovations in CMOS sensor technology, global shutter architectures, and AI-based image processing, machine vision systems now offer superior low-light performance, high dynamic range, and ultra-fast frame rates. onsemi’s portfolio, including the XGS, PYTHON, and Hyperlux sensor families, delivers scalable, power-efficient solutions tailored for both high-resolution and high-speed applications.

The integration of extended vision technologies like LiDAR, iToF and SWIR further expands machine vision’s capabilities, enabling accurate 3D mapping and object detection in dynamic environments. These advancements are pivotal for smart factories, autonomous robotics, and next-generation quality control systems.

Security and Surveillance Cameras

Modern video surveillance demands high dynamic range, low-light sensitivity, and real-time processing to support intelligent monitoring in complex environments. onsemi’s CMOS image sensors, including the Hyperlux LP and Hyperlux LH series, are engineered to meet these requirements at low power consumption. These advanced sensors deliver low noise, high quantum efficiency, and high frame rates critical for capturing fast-moving subjects and maintaining image integrity in challenging lighting conditions. Hyperlux LP is optimized for low-power, compact devices, while Hyperlux LH targets high dynamic range (HDR) applications such as city-wide surveillance and traffic analytics.

Our best-in-class image sensor development ecosystem software reduces design time and accelerates time to market (TTM). The scalability and integration flexibility of our image sensors make them ideal for IP cameras, network video recorders (NVRs), and embedded vision systems. As surveillance systems evolve toward edge intelligence and 24/7 situational awareness, Hyperlux sensors provide the imaging foundation for next-generation security infrastructure.